Restoration of Auster VX123 (part II) ……

As reported previously, we were donated the Auster fuselage and wings which were in poor condition. The fuselage was bead blasted and etch primed by a local firm. See Previous Auster Restoration

Airframe of the Auster

Since then we have stripped the wings and David Dawson repaired the damage caused by the accident and covered the wings with Diatex, a synthetic linen replacement. The wings were painted with two coats of primer in readiness for a top coat of silver in the future and then put into storage.

Auster Wings in Storage

A fairly complete set of drawings were obtained from Leicester Public Records who are the holders of most Auster data since it was manufactured by Taylorcraft in Rearsby, Leicester. One man works on the database just one day a week.

Meanwhile, a contact was made with someone who has connections with a large number of national aircraft museums, and he volunteered to try and source missing items from our fairly long list. So far we have received a tail wheel assembly, rudder, engine bearers, and we were hopeful that he could later deliver an incomplete engine, spinner and propeller, and a missing cowling (see below).

The original owner has cleared out his store and delivered a few more items but that seems to be the lot from his store. Most wooden items were too poor to use but they were used as patterns for new items which are being made.

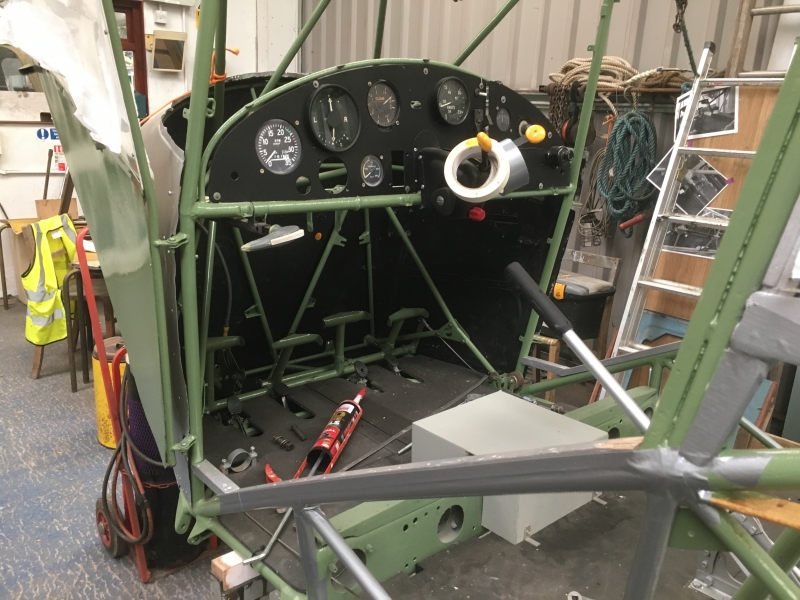

As some members will be aware, the fuselage has been built up with stringers in readiness for cladding, and the cockpit instruments are there with two fakes that are downloaded images with plastic in place of glass. It looks the part for a casual glance. The main problem is sourcing Perspex for the cockpit canopy – far too tricky to make since it has compound curves. However, some flat Perspex has been temporarily fixed in position. Also, we only had one door, so Terry has manufactured the missing one.

Restoration of the Airframe with Engine Mounts and New Fabricated Door

The most recent addition to the much needed Auster project is an engine. It is in pieces, and it is missing a crankshaft and pistons, but we can get around that as the pistons don’t matter for a static display, and for the crankshaft we can use some large diameter tube to mount a propeller on – when we get one. Soon, I will take the pieces away to be blast cleaned and then we can paint them and start to assemble the engine. We are still missing an engine mounting bolt but I am hoping to find someone who knows someone who can do some fancy engineering for us – it is a 5/8 stud with an angled flange and very tricky to make in-house. An ideal solution would be for it to be scanned and additive manufactured – any contacts greatly appreciated.

Recently Donated Engine Parts

This will definitely be a long project due to the spares contact working overseas and therefore not completely on the trail to find missing items for us. But, eventually it will be finished and then in some respects the biggest problem – where are we going to display it?

Well done John and Co.

John, as the new owner of G-ASCH, I’m extremely interested in this project as I believe my aircraft has the starboard wing of ex-G-ARLP, which was ex-VX123.

Dom, Your comments have been passed on to the restoration team … Bloginfo.

Hi Dom, it’s nice to know that bits of VX123/G-ARLP have had extended use. Drop in and say hallo when you’re in the area.